Application-Tested Heat Resistant Elastomers

DuPont heat resistant elastomers are backed by extensive testing, application experts and real-world performance.

In the automotive industry, smaller, more fuel-efficient auto engines are making things hotter under the hood. In energy production, global demand for reliable energy supplies is stretching maintenance intervals.

Whenever the challenge is maintaining high performance in high temperatures and harsh chemicals, DuPont heat resistant elastomers provide a full portfolio of cost-effective choices.

Specifying the Right Material

Often, heat isn’t the only challenge for an application. Specifying a heat resistant elastomer that also has the required combination of flexibility, durability and chemical resistance can be the key to success.

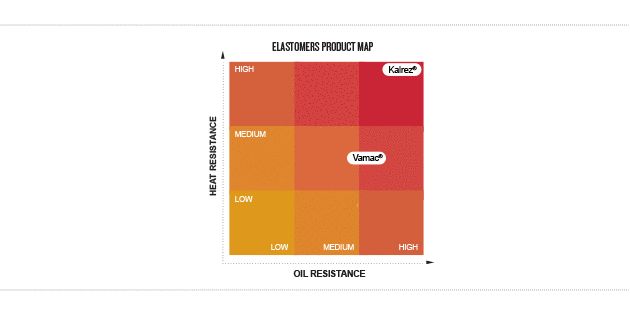

Here is a quick overview of DuPont heat resistant elastomers:

- Vamac® ethylene acrylic elastomer: Heat resistance to 175°C with excellent flexibility, oil and chemical resistance. Vamac® Ultra HT AEM delivers continuous heat resistance to 175°C, with peaks to 200°C.

- Kalrez® perfluoroelastomer parts: Heat resistance to 327°C, and resistance to over 1800 chemicals, with many compounds available for different applications.

Auto Industry Focus: DuPont™ Vamac®

Vamac® ethylene acrylic elastomer (AEM) is the most widely specified elastomer in the automotive industry. It is the material of choice for hoses, dampers, seals, boots, and gaskets for its combination of durable flexibility, and resistance to heat and automotive lubricants.

Many grades of Vamac® are available to provide the exact characteristics needed for specific applications.

Customers demand results in new innovation. Vamac® Ultra HT ethylene acrylic elastomer (AEM) delivers continuous heat resistance up to 180°C, with peaks to 200°C and improved mechanical properties. Developed to handle automotive turbo hoses and air ducts as engine environments become hotter — and harder to handle. With an optimized structure and chemical composition, this next generation of Vamac® delivers significant improvements, especially in the presence of engine and transmission lubricants, or acids in exhaust recirculation and closed crankcase ventilation systems.

Best-in-Class Elastomer Seals: DuPont™ Kalrez®

For the most demanding sealing applications, DuPont™ Kalrez® perfluoroelastomer (FFKM) parts are the superior choice. Proven in the most aggressive applications, its advanced properties help maintain seal integrity, and help reduce both maintenance and operating costs. Kalrez® parts and seals resist over 1,800 different chemicals, while providing the high-temperature stability of PTFE (327°C).

Kalrez® parts are designed with properties to help meet the specific application requirements of many industries. From jet engine lubricants and rocket propellants to downhole oil environments and high-vacuum sealing, Kalrez® parts have been demonstrated to perform in the most demanding applications. Kalrez® parts are available in many compounds as standard O-rings, or can be custom-designed for a unique fit. Production facilities for Kalrez® are ISO 9000 registered and parts are fully traceable.