FFKM Material

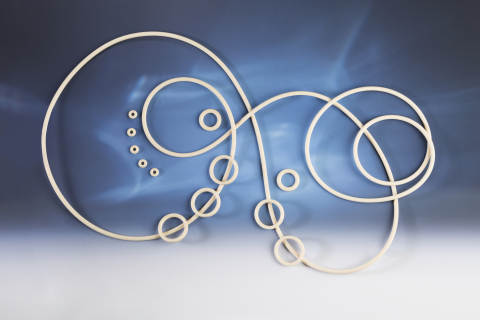

When it comes to sealing technology, M&P Sealing provides a range of efficient sealing solutions. Our latest addition provides exceptional resistance for FFKM materials to chemical attack, high temperatures, and abrasion. Our Chemraz® O-rings are perfect for use in harsh environments where conventional seals will fail to perform.

Also known as perfluoroelastomer FFKM O-rings, these products are a popular choice among our customers, offering excellent resistance capabilities for their equipment. They are widely utilized in the semiconductor, pharmaceutical, and chemical processing industries, among many others.

Our experts at M&P Sealing can help you select the right perfluoroelastomer FFKM sealing solution, ensuring optimal performance in your applications. With our years of experience, state-of-the-art facilities, and commitment to quality, we deliver reliable and efficient sealing solutions to meet the needs of customers in Texas, Louisiana, Colorado, Arkansas, and New Mexico.

Material Description

FFKM material, or perfluoroelastomer, contains higher amounts of fluorine than standard FKM and features higher temperature ratings, up to approximately 325°C (617°F). FFKM also has improved chemical resistance with nearly universal chemical compatibility. This combination of high-performance capabilities makes FFKM seals the premium choice for the most challenging applications.

The first commercially available FFKM seal was produced in the late 1960s. However, widespread manufacturing of FFKM materials did not occur until the late 1980s due to patent restrictions.

FFKM is used in o-rings and seals in environments with high temperatures and/or harsh chemicals in the aerospace, semiconductor, energy, pharmaceutical, and industrial industries.

Greene Tweed’s Chemraz® is the ultimate elastomeric FFKM material. Chemraz® is a polymer of three or more monomers in which all hydrogen positions have been replaced with fluorine. It has the broadest chemical resistance of any elastomeric material.

Grades of FFKM – GT Fluid Compatibility Guide

Data Sheet – Chemraz® 504

Features & Benefits

- Broad chemical compatibility for use with a wide range of harsh solutions

- Lower compression set increases ability to handle temp & pressure variations, shaft misalignment, & o-ring shrinkage

- Low temp capabilities (-30°C/-22°F)

| Primary Industry | Application | Temperature Range | Chemical Compatibility |

|---|---|---|---|

|

|

|

|

Data Sheet – Chemraz® 505

Features & Benefits

- Broad chemical compatibility for use with a wide range of harsh solutions

- Lower compression set increases ability to handle temp & pressure variations, shaft misalignment, & o-ring shrinkage

| Primary Industry | Application | Temperature Range | Chemical Compatibility |

|---|---|---|---|

|

|

|

|

Data Sheet – Chemraz® 510

Features & Benefits

- Broad chemical compatibility

- Low temp capabilities (-30°C/-22°F)

- Higher hardness and density reduces the likelihood of gap extrusion

| Primary Industry | Application | Temperature Range | Chemical Compatibility |

|---|---|---|---|

|

|

|

|

Data Sheet – Chemraz® 517

Features & Benefits

- No carbon black residue

- Low-temp capabilities

- (-30°C/-22°F)

| Primary Industry | Application | Temperature Range | Chemical Compatibility |

|---|---|---|---|

|

|

|

—— |

Data Sheet – Chemraz® 526

Features & Benefits

- Excellent RGD resistance

- Broad chemical resistance

- Meets RGD requirements

- of Total GS EP PVV 142 & NACE TM0297ISO 23936-2/ NORSOK M-710

| Primary Industry | Application | Temperature Range | Chemical Compatibility |

|---|---|---|---|

|

|

|

|

Data Sheet – Chemraz® 555

Features & Benefits

- Superior high temp capability (316°C/600°F)

- Broad chemical resistance in a wide range of media

- Excellent compression set maintains seal integrity in wide temp & pressure variations as well as vibration

| Primary Industry | Application | Temperature Range | Chemical Compatibility |

|---|---|---|---|

|

|

|

|

Data Sheet – Chemraz® 600

Features & Benefits

- High durometer & high-density material helps withstand high pressure & harsh environments

- Broad chemical resistance range

- High-temperature capability

| Primary Industry | Application | Temperature Range | Chemical Compatibility |

|---|---|---|---|

|

|

|

—- |

Data Sheet – Chemraz® 605

Features & Benefits

- High-temperature capability

- Excellent compression set resistance

- Broad chemical compatibility for use with a wide range of harsh solutions

| Primary Industry | Application | Temperature Range | Chemical Compatibility |

|---|---|---|---|

|

|

|

|

Data Sheet – Chemraz® 615

Features & Benefits

- Low compression set at continuous temps up to 324°C (615°F)

- Ability to handle severe thermal cycles

- Excellent chemical resistance

| Primary Industry | Application | Temperature Range | Chemical Compatibility |

|---|---|---|---|

|

|

|

|